Roofing

We are a certified roofing contractor in the state of Iowa

- Check the Better Business Bureau.

- Receive a high end warranty.

- Check the references of the contractor.

OWEN CORNING

BOLD CONTRAST. DEEP DIMENSION. OUTSTANDING PERFORMANCE.

Wind Resistance

Algae Resistance

TruDefinition Color Platform

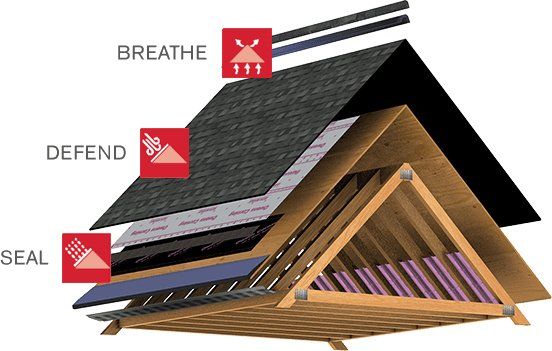

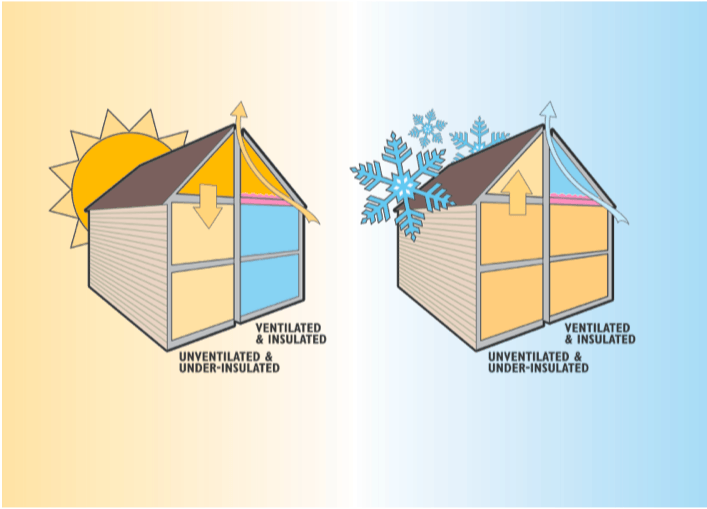

A Healthy Roofing System Starts with a Well-Ventilated Attic.

- Help allow outside air flow naturally upward and out of attic. 2. Promote dry, cool attic.

- Help prevent moisture from becoming trapped in the insulation, structural wood, shingles, and roof deck.

- Help prevent rotting, mildew, drywall damage, peeling paint and warped siding.

- Provide year-round performance for consistent ventilation without energy consumption.

ProEdge® Hip & Ridge Shingles provide a clean and consistent roof line. Their enhanced aesthetic add distinction to your roof line. Attention to details matter.

- There is an added shadow line that provides strong distinction along the ridge line and enhances the overall aesthetics.

- Increased exposure allows for quick installation.

- Color-matched to coordinate with the Owens Corning™ laminate shingle line.

- Perforated for easy separation, and No additional on-site cutting required.

- Pre-applied continues sealant bead aids in quick adhesion.

- Warranty corresponds with the Owens Corning™ Shingle Warranty installed.

- Algae Resistant.

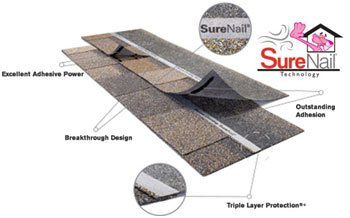

Owens Corning® ProArmor™ Synthetic Roof Underlayment with Fusion Back Coating Technology is strong, durable and repels water unlike #15 felt. It’s also light, easy to install and contributes to safe working conditions.

- Dual-surface slip resistance: Fusion Back Coating Technology paired with an industrial non-woven surface provides excellent walking conditions during shingle application even on steeply pitched roofs.

- Repels moisture and helps provide protection against water infiltration.

- Resists stretching and tearing around fasteners.

- Available in 42-inch lightweight rolls for easy installation.

- 10- Year Limited Warranty.

- For use under asphalt shingles only.

Our Team Can Handle Any Size Project Your Company Needs Done

TPO Roofs

What Is a TPO Roof? TPO stands for thermoplastic polyolefin, a single-ply roofing membrane that covers the surface of the roof. The name is a bit misleading, because rather than being a plastic, TPO is actually one of a few different types of rubber, usually a blend of polypropylene and ethylene-propylene rubber.

Thermoplastic Polyolefin is a single-ply roofing membrane that is one of the fastest growing commercial roofing systems on the market. TPO roofing systems are made up of a single layer of synthetics and reinforcing scrim that can be used to cover flat roofs.

TPO membranes are manufactured in sheets that are 10, 12 or 20 feet wide. These sheets are then rolled up and taken to the commercial facility. TPO has gained industry acceptance with the natural reflective surface to reflect UV rays. As reported by the National Roofing Contractors Association (NRCA) TPO takes up about 40% of the commercial roofing market share.

- Polyisocyanurate (Polyiso) – The most used insulation type for roofing applications, Polyiso is more expensive but pays off with a higher R-value rating.

- Expanded Polystyrene (EPS) – With the highest R-value per dollar, EPS is used for roof, wall and floor insulation. EPS can be used for ground contact and does not retain water over time.

- Extruded Polystyrene (XPS) – Usually defined by the blue, green or pink color, XPS falls in-between Polyiso and EPS in the range of price and performance. XPS is semipermeable with a perm rating of 1.

The TPO membrane can be attached to the cover board with a bonding adhesive or mechanically fastened. When the membrane is rolled out, the contractor then returns and uses a hot-air gun to hot air weld the seams together.

Built-Up Roofs

Built up roof membranes, referred to by the acronym BUR, have been in use in the U.S. for more than 100 years. These roof systems are commonly referred to as "tar and gravel" roofs. BUR systems generally are composed of alternating layers of bitumen and reinforcing fabrics that create a finished membrane. The number of plies in a cross section is the number of plies on a roof: The term "four plies" denotes a four ply roof membrane construction. Sometimes, a base sheet, used as the bottommost ply, is mechanically fastened. Built up roofs generally are considered to be fully adhered if applied directly to roof decks or insulation.

Fluid Applied/Roof Coating

Fluid Applied Roofs insulate your building and pays for itself within 5 to 7 years. In addition to the added durability of a newly coated roof, these systems can increase the lifespan of your existing roof and decrease the probability your roof will be damaged. Our expertise in the roof coatings industry makes sure that you get the best bang for your buck. With year round, cost-effective commercial roof solutions we offer a solution for any business, any size, guaranteed.

Shrink-wrap

Shrink wrap can be applied in the same way as a tarp and offers a wide variety of benefits over products that aren’t able to be custom fit.

Shrinking and welding shrink wrap offers superior weather protection in every environment.

Dr. Shrink’s high quality material is more durable and flexible than a tarp, which lends to a longer lasting cover for short or long term needs.

All shrink wrap has UV inhibitors to protect it from UV breakdown.

Consistent results for a clean, professional look on every project.

Flame retardant shrink wrap that meets or exceeds NFPA 701 guidelines is available.